Product Category

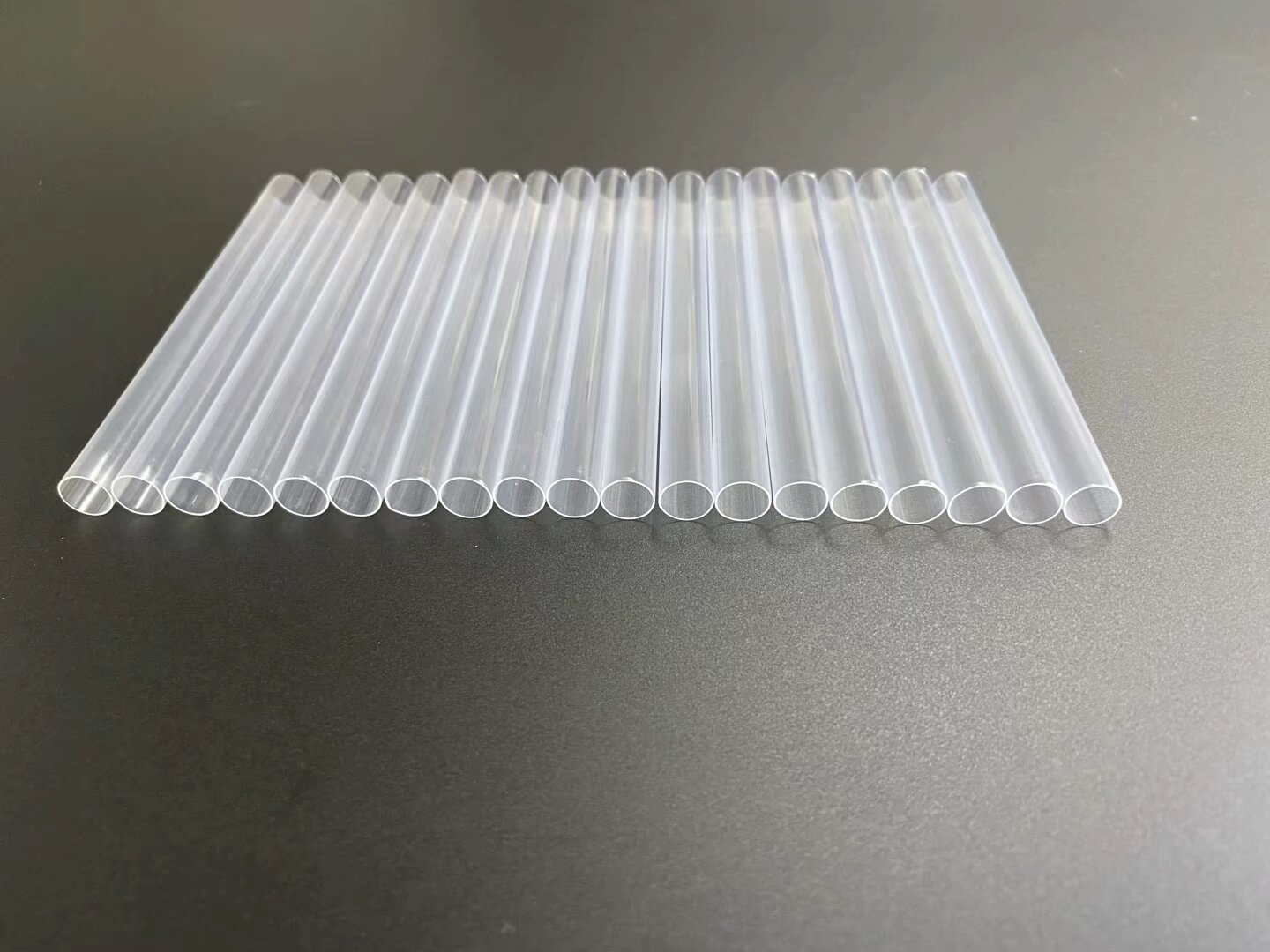

Medical-Grade FEP Heat-Shrink Tube for Microcatheters

Key features of medical FEP heat shrink tubing:

1. Biocompatibility: Medical FEP heat shrink tubing is a biocompatible material that meets the requirements of medical devices and does not trigger immune or allergic reactions in the human body. This makes it suitable for the manufacture of medical devices and implants.

2. High-Temperature Resistance: FEP material exhibits excellent high-temperature resistance and can withstand high-temperature sterilization and disinfection processes without deformation or degradation. This makes it suitable for devices that require regular sterilization in medical environments.

3. Compatibility with autoclave, gamma, ETO, steam, and dry heat sterilization.

4. Transparency: FEP material has a high degree of transparency, making it suitable for medical applications requiring visual inspection or optical observation, such as endoscopes and testing equipment. It can also be produced in various colors.

5. Good Insulation: FEP heat shrink tubing has excellent insulating properties and can be used for insulating wires and cables, helping to reduce electrical failures and hazards.

6. Abrasion Resistance: FEP heat shrink tubing exhibits a certain degree of abrasion resistance, protecting internal components from mechanical stress and extending their service life.

7. Easy to install: Medical FEP heat shrink tubing can be quickly shrunk to the required size by heating, simplifying the installation process and ensuring a tight covering of the protected parts. The seal can prevent the entry of bacteria, fungi, mold, etc.

Description

Tags

| Product name | Medical-Grade FEP Heat-Shrink Tube for Microcatheters |

| Product price | $0.20~1.00 |

| Material | Medical FEP |

| Specification | customized specified |

| Standard | ISO13485 ;FDA ,ROHS, Reach , |

| MOQ | 100meters |

| Delivery | 7-15 days |

| Usage | This medical-grade FEP heat shrink tubing is designed for secure, temporary bundling, strain relief, or encapsulation of microcatheter components during assembly. It peels easily after heat shrinking without leaving residue, making it ideal for sterile precision medical device manufacturing. |

| Main Features | 1. After shrinking, it separates cleanly along pre-weakened seams for easy removal without damaging delicate components.

2. Medical-grade FEP material – Fluorinated ethylene propylene (FEP) is biocompatible and chemically resistant, meeting USP Class VI and ISO 10993 standards. 3. Heat-shrinkable – Heat creates a snug, conformable fit (typical shrink ratio: 1.3:1 or 1.6:1), providing secure temporary protection. 4. Sterilization compatibility – Withstands gamma radiation, ethylene oxide (EtO), and autoclave sterilization, making it suitable for use in sterile medical environments. 5. Thin-walled and flexible – Maintains microcatheter maneuverability while minimizing bulk. 6. Transparent – Allows for visual inspection of underlying components during assembly. 7. Low-friction and non-stick – Facilitates smooth catheter insertion/removal without sticking. |

| Application | 1. Microcatheter Assembly – Temporary bundling of lumen, guidewire, or catheter shaft during manufacturing. 2. Strain Relief – Strengthens connection points prior to epoxy curing or permanent bonding.

3. Sterile Barrier – Protects sensitive areas during handling/transport (peeled off after sterilization). 4. Label/Sleeve – Marks components for identification (removed after handling). 5. Minimally Invasive Devices – Used in neurovascular, cardiovascular, and electrophysiology catheters. |

| Samples | Free samples,you just need to pay for the courier charges |

| Places of origin | Shenzhen China |