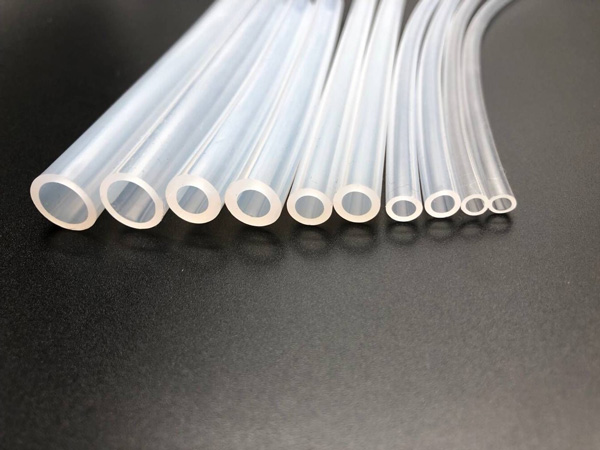

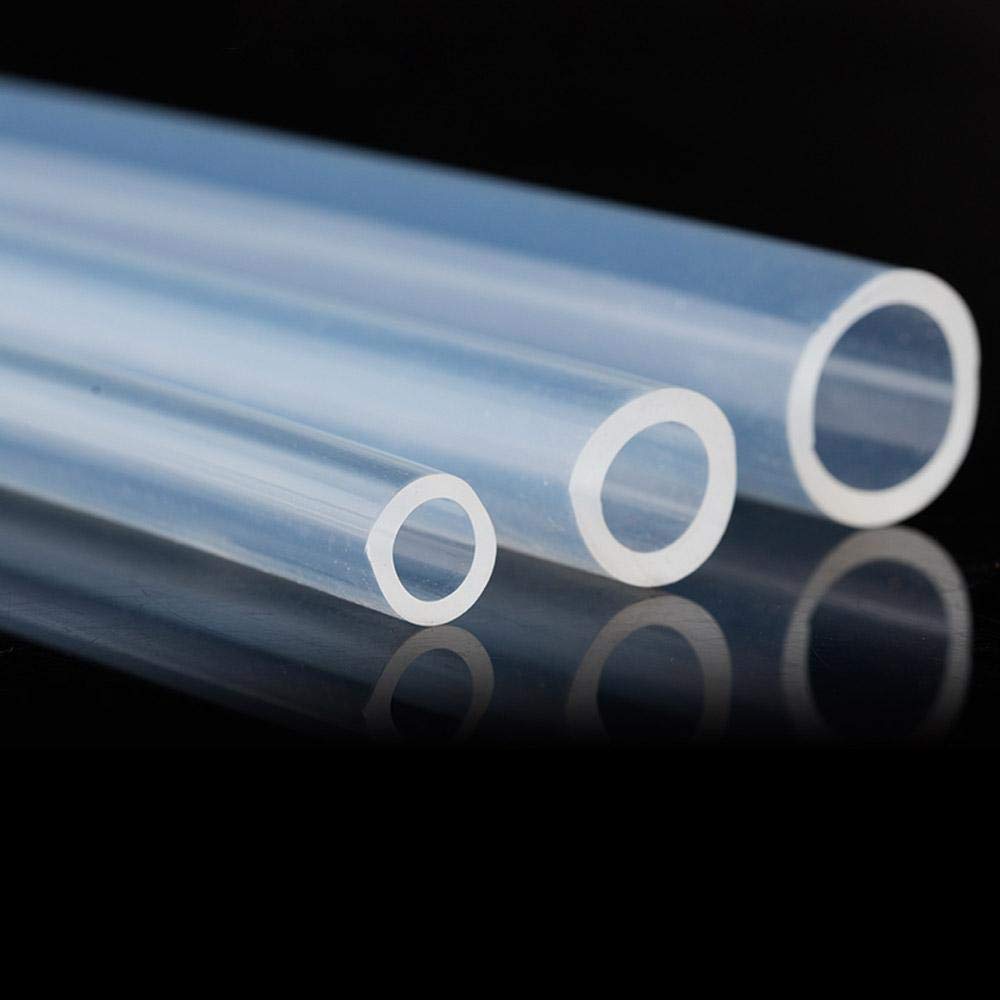

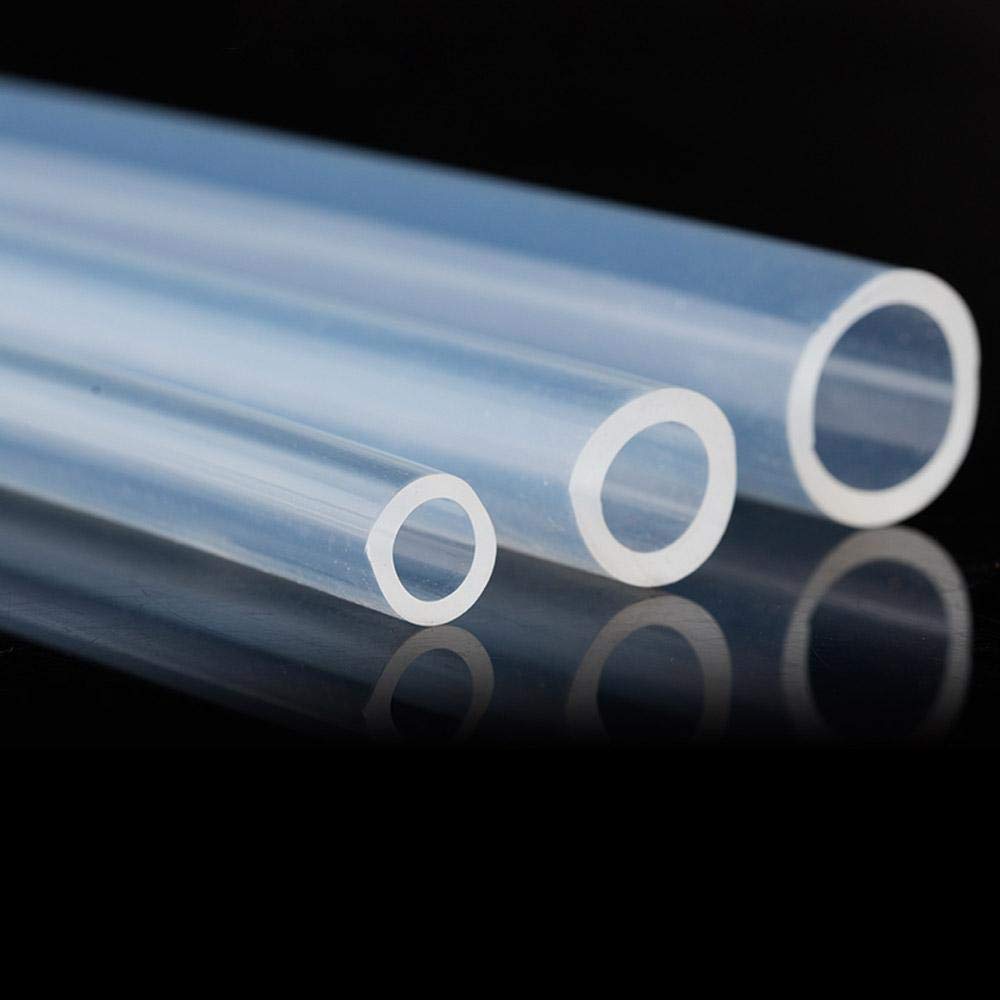

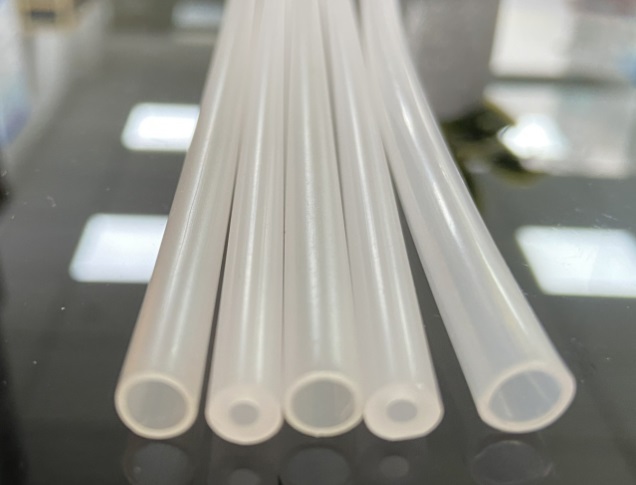

Made from silicone rubber, silicone tubing is a flexible, robust, high-performance tube with outstanding resistance to temperature extremes, UV radiation, and ozone. Because of its non-toxic, hypoallergenic, and biocompatible qualities, it is widely employed in several sectors including medical, food & beverage, and pharmaceutical. For uses requiring a safe and dependable material for fluid transfer or protection, silicone tubing also provides great flexibility, simplicity of sterilizing, and resistance.

Forbest offers a wide range of silicone tubing products, including platinum cured tubing, designed for medical use. Their industrial grade silicone tubing offers excellent performance and is affordable. Its clean, non-toxic properties and resistance to high temperature fluctuations make it popular in the medical field. Silicone extrusion products are suitable for sealing in sectors like chemical, pharmaceutical, food, electronics, and machinery due to their strong ozone, solvent, and electrical insulating capabilities.

-

High-Quality Medical and Food-Grade Silicone Tubing

High-Quality Medical and Food-Grade Silicone TubingDesigned to satisfy strict medical and food industry standards, Best provides a large selection of silicone tubing including platinum-cured choices. Our medical-grade silicone tubing guarantees lowest extractables, therefore guaranteeing performance and safety for delicate uses. Designed in our modern cleanroom, our goods are ideal for settings needing great non-toxicity and cleanliness.

-

Superior Performance Over Multiple Fields

Superior Performance Over Multiple FieldsIdeal for both medical and industrial applications, finest silicone tubing has remarkable flexibility and temperature resistance. Forbest’s silicone solutions offer durability and long-term dependability whether in food processing, medical devices, or other uses calling for high-performance tubing. The rubber-like suppleness of the material guarantees constant performance even under demanding conditions.

-

Environmental-Friendly and Versatile Extrusions

Environmental-Friendly and Versatile ExtrusionsOur silicone extrusions—which include silicone cord—have profiles ranging from D to U, L to P, T form. Industries like food, pharmaceutical, chemical, and electronics would find these adaptable goods fit. Excellent resistance to ozone, UV, solvents, and severe temperatures (-50℃ to 300℃ guarantees long-lasting, environmentally friendly performance in many uses from our silicone tubing.

-

Long-lasting and Durable Silicone Products

Long-lasting and Durable Silicone ProductsExcellent quality and longevity are well known features of top silicone tubing and cord. Our goods are meant for long service life without cracking or deformation; they provide great flexibility, wear resistance, and simple customizing. Perfect for culinary, electronics, automotive, and aerospace sectors, Forbest silicone tubing can resist demanding environments and keep ideal performance over time.

Best provides a large range of premium silicone tubing with platinum-cured variants meant to reduce extractables. Made in a state-of- the-art clean environment to fulfill exact hygienic standards, our silicone tubing is ideal for medical, food, and industrial uses. Forbest silicone tubing offers dependable performance in challenging conditions; it is well-known for its adaptability and durability to extreme temperatures (-50°C to 300°C, weather, UV, and ozone). Our tubing guarantees a precise fit for your particular demand by means of adjustable profiles and sizes, so providing durability and great performance at reasonable rates.

Forbest provides premium silicone tubing fit for many different sectors. Our platinum cured silicone is perfect for medical uses where purity is very important since it guarantees minimum extractables. From -50°C to 300°C, the tube is made to resist severe temperatures, so offering flexibility for both industrial and food-grade applications. Furthermore, our modern clean room facilities guarantee that our products are produced in a regulated atmosphere, so guaranteeing the best standards of quality and cleanliness. With Forbest, you can rely on a flexible, strong, dependable silicone tubing solution.

-

Initial Consultation

First in our design process at Forbest is extensive client consultation. We explore the specifics of your needs, knowledge of the intended use for the silicone tubing, the necessary temperature range, and any legal requirements that have to be followed. This first step is absolutely essential for customizing the design to fit your exact needs.

First in our design process at Forbest is extensive client consultation. We explore the specifics of your needs, knowledge of the intended use for the silicone tubing, the necessary temperature range, and any legal requirements that have to be followed. This first step is absolutely essential for customizing the design to fit your exact needs. -

Material Selection

Drawing on the data, we choose the suitable silicone grade. Platinum-cured silicone is used in medical applications to guarantee lowest extractables and preserve the best degree of purity. We select materials for industrial applications that provide outstanding performance at reasonable rates, therefore guaranteeing dependability and longevity.

Drawing on the data, we choose the suitable silicone grade. Platinum-cured silicone is used in medical applications to guarantee lowest extractables and preserve the best degree of purity. We select materials for industrial applications that provide outstanding performance at reasonable rates, therefore guaranteeing dependability and longevity. -

Customizing Design

Our design staff then produces a tailored design for the silicone tubing. We take into account elements including the elasticity, adaptability, and resistance required for the particular use. Our modern clean room facilities help us to generate tubing fit for both medical and food-grade uses, therefore guaranteeing that the end result satisfies all required standards.

Our design staff then produces a tailored design for the silicone tubing. We take into account elements including the elasticity, adaptability, and resistance required for the particular use. Our modern clean room facilities help us to generate tubing fit for both medical and food-grade uses, therefore guaranteeing that the end result satisfies all required standards. -

Prototyping and Testing

We build prototypes of the intended tubing before mass manufacturing. These prototypes are tested extensively to guarantee they satisfy our exacting criteria on safety, performance, and quality. This stage lets us make any required changes to the design, so guaranteeing that the resultant product is ideal for your use.

We build prototypes of the intended tubing before mass manufacturing. These prototypes are tested extensively to guarantee they satisfy our exacting criteria on safety, performance, and quality. This stage lets us make any required changes to the design, so guaranteeing that the resultant product is ideal for your use.

-

Advanced Manufacturing Techniques

Our production start after the design is completed. Our talented staff creates the silicone tubing using cutting-edge manufacturing methods. Modern tools help us to guarantee accuracy and uniformity in every tube we make.

Our production start after the design is completed. Our talented staff creates the silicone tubing using cutting-edge manufacturing methods. Modern tools help us to guarantee accuracy and uniformity in every tube we make. -

Standards of Quality

We keep tight quality control policies all through the manufacturing process. Every tube is checked to satisfy our exacting criteria for durability, flexibility, and purity. Our silicone tubing's constant performance shows clearly our dedication to excellence.

We keep tight quality control policies all through the manufacturing process. Every tube is checked to satisfy our exacting criteria for durability, flexibility, and purity. Our silicone tubing's constant performance shows clearly our dedication to excellence. -

Temperature Resistance

Our silicone tubing is made to resist rather large temperature swings, from -50℃ to 300℃. This qualifies for a broad spectrum of uses, including industrial machinery, food processing tools, and medical devices, where dependability and performance rule most importantly.

Our silicone tubing is made to resist rather large temperature swings, from -50℃ to 300℃. This qualifies for a broad spectrum of uses, including industrial machinery, food processing tools, and medical devices, where dependability and performance rule most importantly. -

Several Uses

Our silicone tubing's adaptability lets it find application in many different sectors. Applications in electronics and machinery, chemical and pharmaceutical sectors, or even food and medical sectors—our tubing offers the longevity and performance required to fulfill various needs.

Our silicone tubing's adaptability lets it find application in many different sectors. Applications in electronics and machinery, chemical and pharmaceutical sectors, or even food and medical sectors—our tubing offers the longevity and performance required to fulfill various needs.

-

What are the main benefits of using silicone tubing?

Silicone tubing offers several advantages, including excellent flexibility, resistance to extreme temperatures (-50°C to 300°C), and high durability. It is also non-toxic, making it suitable for medical and food-grade applications. Additionally, silicone tubing is resistant to weathering, UV, and ozone, ensuring long-lasting performance.

-

Is silicone tubing suitable for medical applications?

Yes, silicone tubing is highly suitable for medical applications. It is biocompatible, non-toxic, and has low extractables, making it safe for use in medical devices and equipment. Its flexibility and durability also make it ideal for applications requiring precise fluid transfer and handling.

-

Can silicone tubing be customized to specific dimensions and profiles?

Absolutely. Forbest offers a wide range of silicone tubing profiles, including D, U, L, P, and T shapes. We can also customize tubing dimensions and profiles based on customer specifications or samples, ensuring that you get the exact product you need for your application.

-

How does silicone tubing perform in extreme temperature conditions?

Silicone tubing performs exceptionally well in extreme temperature conditions. It can withstand temperatures ranging from -50°C to 300°C without losing its flexibility or integrity. This makes it suitable for applications where temperature fluctuations are common, such as in industrial processes and food processing equipment.

-

What industries commonly use silicone tubing?

Silicone tubing is used in a variety of industries, including medical, food and beverage, automotive, aerospace, electronics, and pharmaceuticals. Its versatility, durability, and resistance to various environmental factors make it a popular choice for many applications in these sectors.