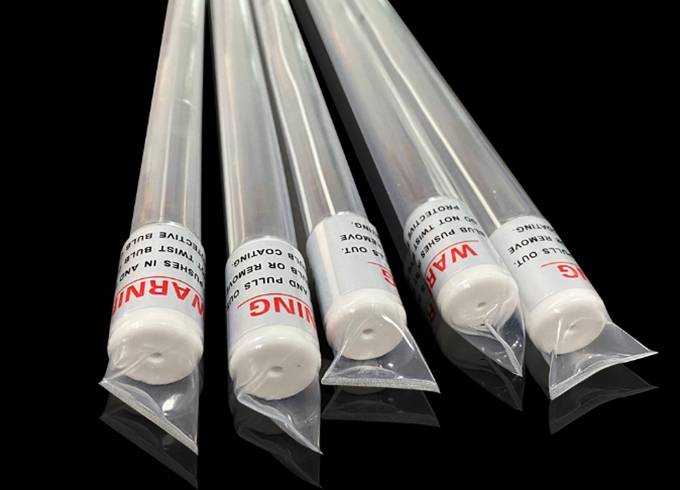

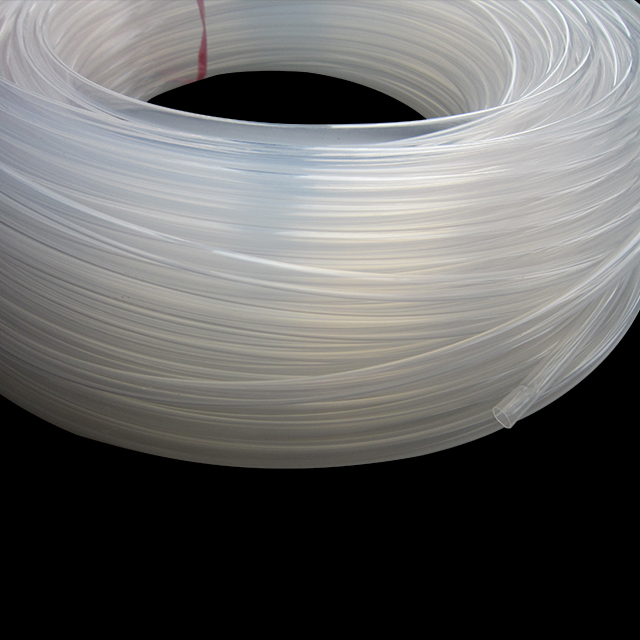

FEP shrinkable tube Made of FEP material, particularly suited to protect UV lights, UV lamp cover is a heat shrinkable tube. It may be utilized in the temperature range of -60℃~205℃ and has great high temperature resistance. Furthermore strong chemical stability and light transmittance help to guarantee the regular functioning and service life of UV lamps and so shield them from outside environmental effects.

Forbest’s FEP heat shrink tube is a versatile protective solution, commonly used as a UV lamp cover due to its superior high-temperature resistance. Capable of withstanding continuous operating temperatures up to 200°C, it shrinks at just 110°C. Initially designed for UVA lamps in electronic mosquito repellents, it is now also used for incandescent lamps. The FEP material provides a durable, shatterproof coating, effectively containing any glass or mercury from a broken lamp tube, and resists degradation from both heat and UV radiation, ensuring the safety and integrity of the lamp. Additionally, this FEP tube finds applications in medical devices and electronics, offering reliable insulation protection.

-

High-performance FEP heat shrink tubing

High-performance FEP heat shrink tubingForbest’s FEP heat shrink tubing has high temperature tolerance, with a maximum continuous operating temperature of 200°C and a shrinking temperature of 110°C. Originally used for UV lampshades, FEP materials can effectively prevent glass and mercury leakage when the bulb breaks, and will not be affected by ultraviolet rays or high temperatures, ensuring the safety and long-term stability of the lampshade.

-

Medical-grade FEP heat shrink tubing

Medical-grade FEP heat shrink tubingForbest provides ISO13485-certified medical-grade FEP heat shrink tubing, which is suitable for high-temperature heat shrink processes. The tubing has strong chemical stability and can be sterilized by gas or steam to meet different customized needs. It provides transparent colors and a variety of shrink ratio options (up to 2:1), and is widely used in medical catheters and other fields.

-

UV lamp protection

UV lamp protectionFEP heat shrink tubing is widely used in the coating of UV lamps such as T5, T6, and T8 to reduce the risk of glass contamination. FEP materials can effectively prevent the leakage of harmful substances when the lamp is broken, and will not become brittle or fade in long-term use, maintaining excellent UV resistance.

-

Wide Application and Excellent Performance

Wide Application and Excellent PerformanceForbest’s FEP heat shrink tubing is not only suitable for lampshade protection, but also widely used in packaging, strain relief and other industries. Its high temperature resistance, UV resistance, non-fading and non-brittleness characteristics make it an ideal choice in the industrial and medical fields, providing reliable protection and long-lasting service life.

Forbest presents its premium FEP Heat Shrink Tube UV Lamp Covers, designed for superior protection and performance. Our FEP tubing offers a maximum continuous working temperature of 200°C, with a shrink temperature of only 110°C. Initially developed for UV lamps in electronic fly killers, it has proven to be the ultimate material for shatterproofing lamps, safely containing glass and mercury in case of breakage without degradation from heat or UV emissions. Our ISO13485 certified medical-grade FEP tubing is also ideal for medical applications, providing custom sizes, colors, and shrink ratios for precise fit and functionality.

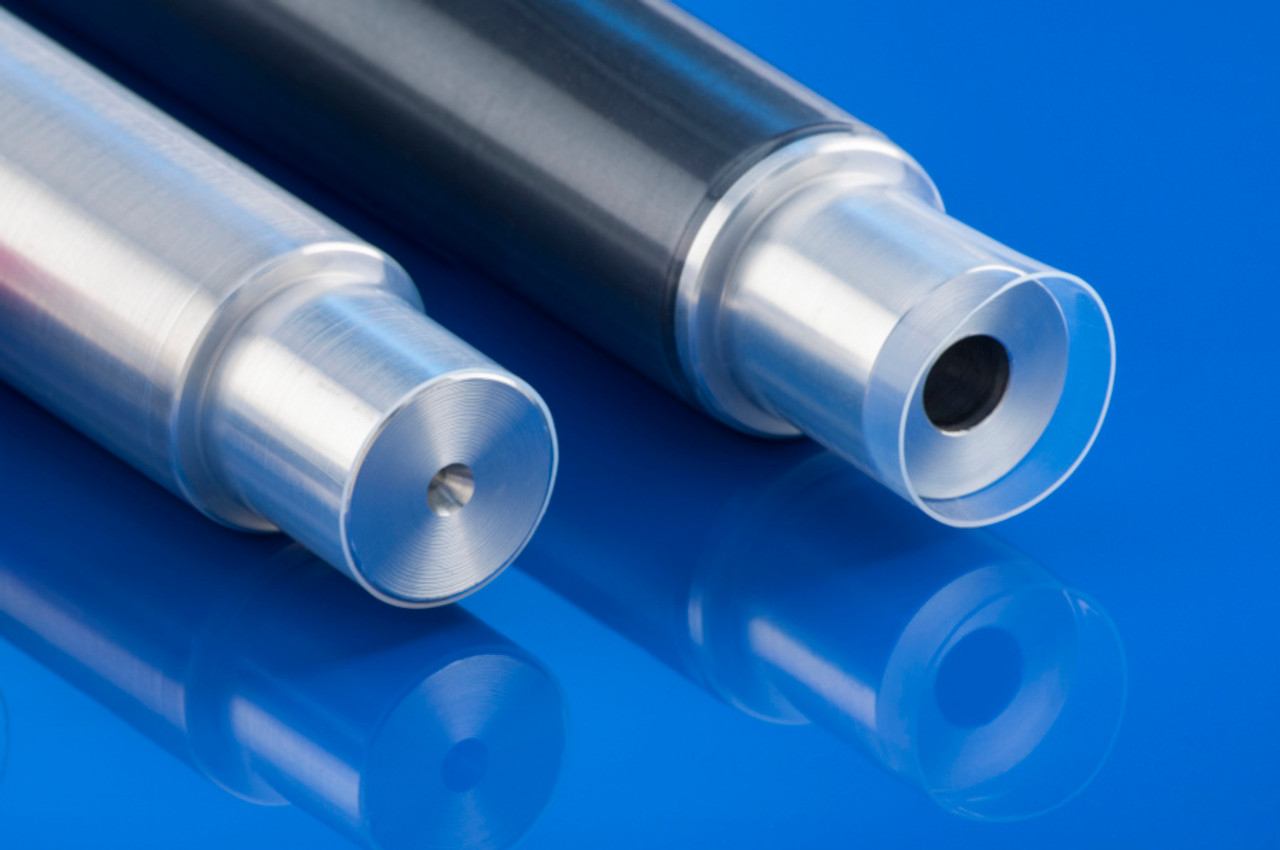

Forbest is the leading provider of high-quality FEP heat shrink tubes and roller covers, offering exceptional performance and versatility. Our FEP heat shrink tube UV lamp covers are designed to provide superior protection and insulation, suitable for a wide range of applications, including medical equipment and electronics. Made from premium FEP material, these products offer excellent chemical stability, high transparency, and a wide operating temperature range of -65℃ to 200℃. Our FEP roller covers are also designed to enhance efficiency and reduce particle accumulation in various industries, ensuring smooth and reliable operations. With ROHS certification and a strong supply capability, Forbest is committed to delivering reliable and environmentally friendly solutions that meet your needs.

-

Demand Analysis

Accurately grasp the customer's detailed requirements for the size, shape, color, etc. of the FEP heat shrink tube UV lampshade, such as the size of different models of UV lamps, specific colors to be integrated into product design, etc., and understand their expectations for performance indicators such as temperature resistance and shrinkage ratio to ensure that the product fits the actual application scenario.

Accurately grasp the customer's detailed requirements for the size, shape, color, etc. of the FEP heat shrink tube UV lampshade, such as the size of different models of UV lamps, specific colors to be integrated into product design, etc., and understand their expectations for performance indicators such as temperature resistance and shrinkage ratio to ensure that the product fits the actual application scenario. -

Design drawings

Use CAD software to carefully draw the processing drawings of FEP heat shrink tube UV lampshade, accurately mark key parameters such as size and shrinkage ratio, and take into account the melting point and chemical inertness of FEP materials, so as to provide detailed and accurate processing guidance for subsequent production.

Use CAD software to carefully draw the processing drawings of FEP heat shrink tube UV lampshade, accurately mark key parameters such as size and shrinkage ratio, and take into account the melting point and chemical inertness of FEP materials, so as to provide detailed and accurate processing guidance for subsequent production. -

Technical communication

In-depth exchanges with the production department on design drawings and technical requirements, detailed explanation of FEP material characteristics and processing precautions, to ensure that production personnel fully understand customer needs and product standards, and lay the foundation for the production of high-quality products.

In-depth exchanges with the production department on design drawings and technical requirements, detailed explanation of FEP material characteristics and processing precautions, to ensure that production personnel fully understand customer needs and product standards, and lay the foundation for the production of high-quality products. -

Production coordination

CAD personnel follow up the production throughout the process, promptly solve problems such as size deviation and material supply, and work closely with the production department to ensure that the FEP heat shrink tube UV lampshade is delivered on time and meets quality standards to meet customer expectations.

CAD personnel follow up the production throughout the process, promptly solve problems such as size deviation and material supply, and work closely with the production department to ensure that the FEP heat shrink tube UV lampshade is delivered on time and meets quality standards to meet customer expectations.

-

Precision design

Based on customer needs, Forbest uses professional software to carefully draw FEP heat shrink tube UV lampshade design drawings, accurately presenting details such as size and shape, providing a detailed blueprint for subsequent production, and ensuring that the product fits the application scenario.

Based on customer needs, Forbest uses professional software to carefully draw FEP heat shrink tube UV lampshade design drawings, accurately presenting details such as size and shape, providing a detailed blueprint for subsequent production, and ensuring that the product fits the application scenario. -

Strict material selection

Selected high-quality FEP materials have excellent high temperature resistance and UV resistance. The continuous working temperature can reach 200°C, and the shrinking temperature is only 110°C. It is chemically inert and ensures that the lampshade has stable performance in high temperature and strong light environments, and is not easy to age or fade.

Selected high-quality FEP materials have excellent high temperature resistance and UV resistance. The continuous working temperature can reach 200°C, and the shrinking temperature is only 110°C. It is chemically inert and ensures that the lampshade has stable performance in high temperature and strong light environments, and is not easy to age or fade. -

Fine processing

Adopting advanced production equipment and technology, the FEP material is precisely processed, and the wall thickness, shrinkage ratio and other parameters of the heat shrink tube are strictly controlled. The customized shrinkage ratio of 1.6:1 to 2:1 can be achieved to meet the adaptation needs of lamps of different diameters and ensure that the lampshade fits the surface of the lamp tube tightly.

Adopting advanced production equipment and technology, the FEP material is precisely processed, and the wall thickness, shrinkage ratio and other parameters of the heat shrink tube are strictly controlled. The customized shrinkage ratio of 1.6:1 to 2:1 can be achieved to meet the adaptation needs of lamps of different diameters and ensure that the lampshade fits the surface of the lamp tube tightly. -

Quality Control

From raw materials arriving the plant to completed goods leaving the factory, strict quality inspection is carried out all during the manufacturing process. Every process is closely examined to find and fix deviations in a timely manner, so guaranteeing that the FEP heat shrink tubing UV lampshade has accurate dimensions, smooth surface, and good shrinkage performance, so satisfying high standards of quality and giving consumers premium goods.

From raw materials arriving the plant to completed goods leaving the factory, strict quality inspection is carried out all during the manufacturing process. Every process is closely examined to find and fix deviations in a timely manner, so guaranteeing that the FEP heat shrink tubing UV lampshade has accurate dimensions, smooth surface, and good shrinkage performance, so satisfying high standards of quality and giving consumers premium goods.

-

What are the temperature tolerances of FEP Heat Shrink Tube UV Lamp Covers?

FEP Heat Shrink Tube UV Lamp Covers boast excellent temperature resistance, with a maximum continuous operating temperature of 200°C and a shrink temperature as low as 110°C. This means they can work reliably in high-temperature environments, while also being able to shrink at a relatively low temperature without damaging the UV lamps or other equipment.

-

How does the FEP material protect UV lamps?

The FEP material used for the lamp covers is shatterproof, safely containing glass and mercury if the lamp breaks. Importantly, it doesn't degrade under the heat or UV light emitted by the lamps, ensuring long-lasting protection and maintaining the integrity of the lamp enclosure.

-

Can the FEP Heat Shrink Tube UV Lamp Covers be customized?

Yes, the FEP Heat Shrink Tube UV Lamp Covers can be customized to meet specific requirements. They can be tailored in terms of size, colors, and shrink ratios. The standard color is transparent, but other colors can be requested. Custom shrink ratios up to 1.6:1, 1.8:1, or 2:1 are available, and the tubes can be cut to the desired length as per the customer's specifications.

-

Are there any industry standards or certifications for these lamp covers?

While the lamp covers themselves may not have specific certifications, the FEP material used in their production is known for its high quality and reliability. Forbest, the company producing these covers, may have certifications related to their manufacturing processes and quality control systems, ensuring that the products meet high standards of quality and performance.

-

What are some common applications for FEP Heat Shrink Tube UV Lamp Covers?

These lamp covers are primarily used for UV lamps in electronic fly killers and white lights, providing shatterproof protection. They are also suitable for various packaging applications and strain relief applications, where protection and durability are essential.