FEP hose is resistant to weather and has a high capacity to tolerate UV radiation. As a result, even if it is used for a long period, FEP Hose will not show signs of aging, degradation, yellowing, or other unpleasant occurrences.

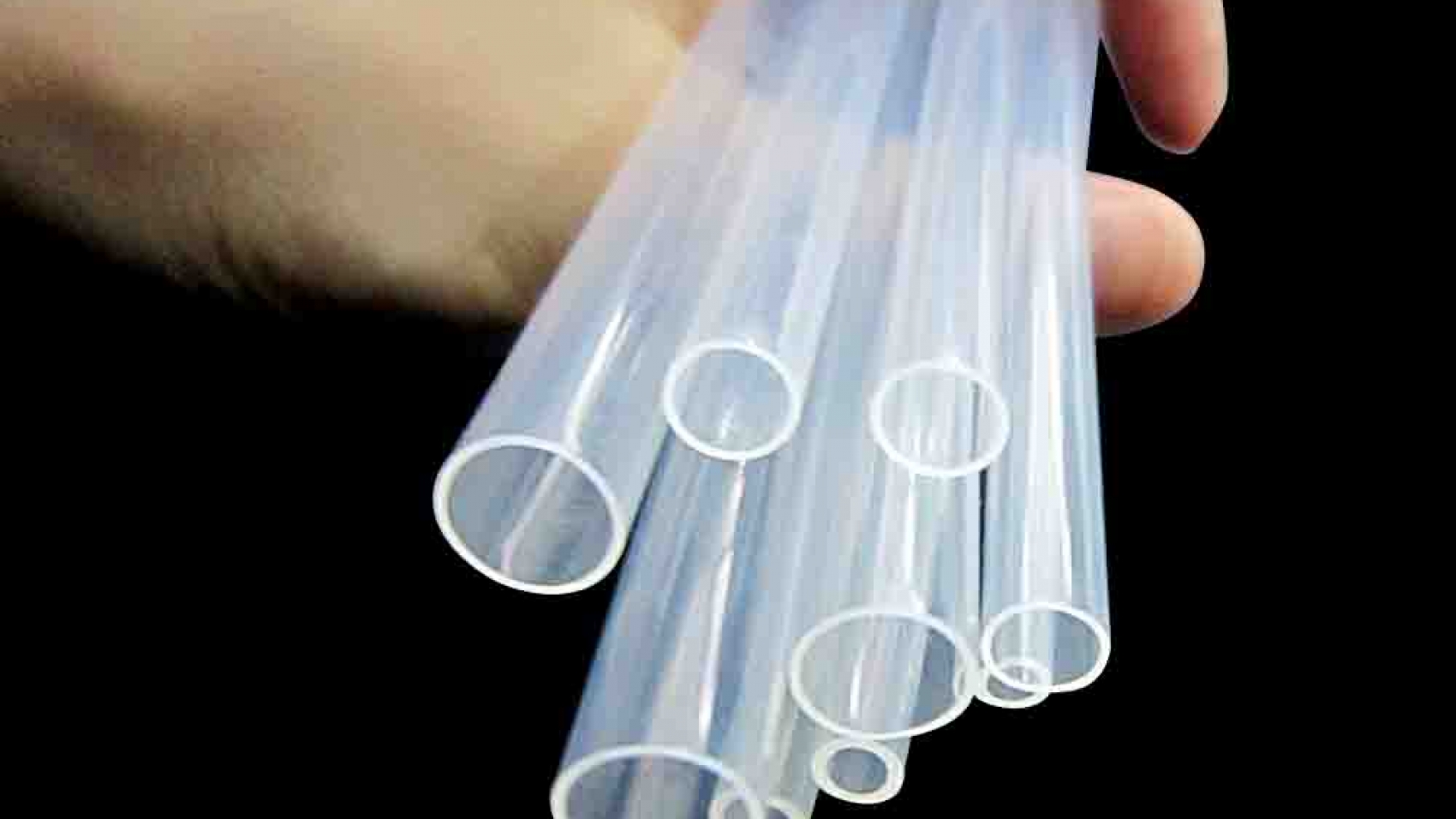

The wall thickness of the FEP Tubing is highly consistent, and the variance in rupture strength is typically minimal.

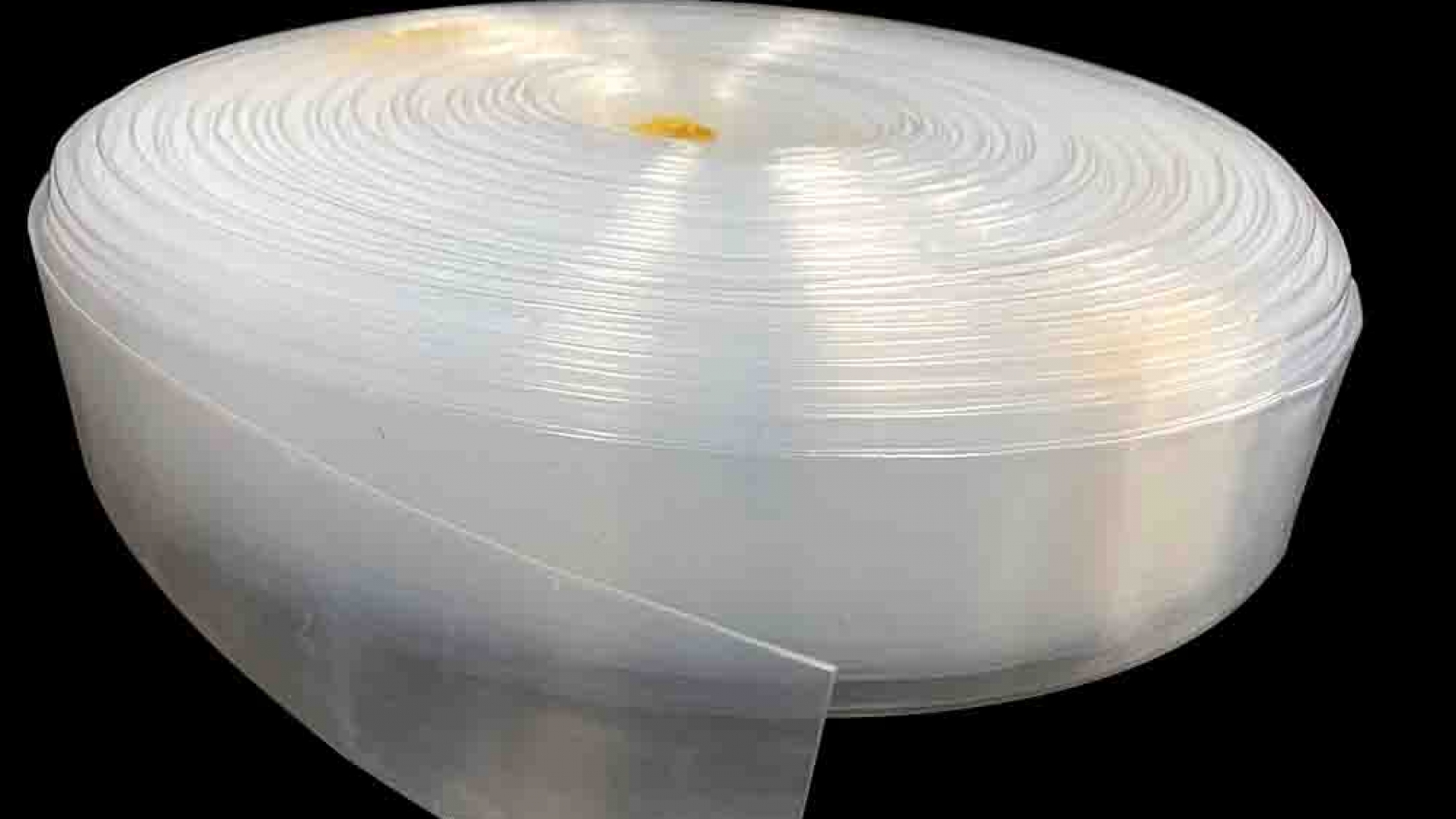

As a result, even if it ruptures, there will be no splashing, substantially improving safety. However, this type of fluorine plastic raw material product has a unique feature in that it requires further processing to produce the required output. In reality, FEP tubing is processed in this manner, with inflation serving as the secondary processing technique.

As a result, even if it ruptures, there will be no splashing, substantially improving safety. However, this type of fluorine plastic raw material product has a unique feature in that it requires further processing to produce the required output. In reality, FEP tubing is processed in this manner, with inflation serving as the secondary processing technique.

The cutting method is similar to that of metal cutting, but it should be noted that the blank body must be placed for 24 hours before cutting; welding is done in a special clamp, and a certain pressure must be applied Only possible; the main lining is made of ferrous metal, primarily for anti-corrosion effect

If it is a general-purpose shrink tube, it will undoubtedly become yellow after a period of usage, leading in a reduction in the tube’s light transmittance. When the FEP Hose is utilized as a shrink tube, however, the outcome is rather different.

The advantages of FEP tubes as shrink tubes and fluoroplastic processing features If it is used as a shrink tube, you must select an appropriate tube; otherwise, not only will the desired effect be lost, but it may also age prematurely and fail. The FEP pipeTube is the one I wish to suggest to everyone here.