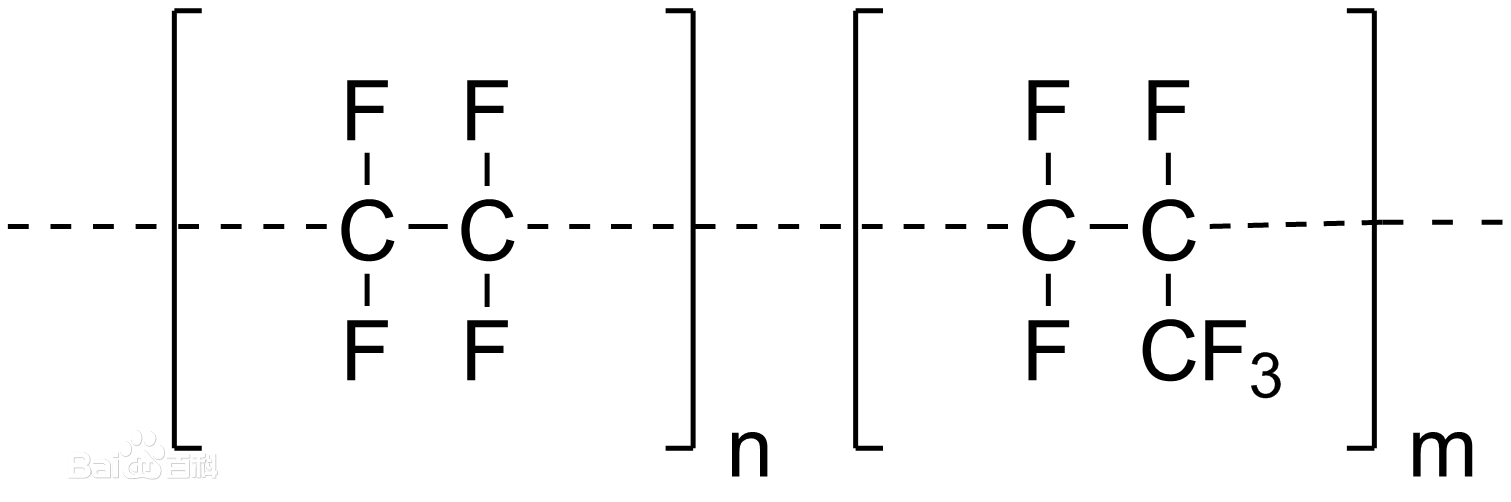

FEP resin, like PTFE, has a completely fluorinated structure. The difference is that part of the fluorine atoms in the main chain of PTFE are replaced by trifluoromethyl (-CF3).

The structural formula is as follows:

It can be seen that although both FEP resin and polytetrafluoroethylene are composed of fluorocarbon elements, the carbon chain is completely surrounded by fluorine atoms, but FEP has branches and side chains on the main chain of its macromolecule.

This structural difference has no significant effect on the upper limit of the temperature range of the material under long-term stress. The upper limit temperature of FEP is 200°C, while the maximum use temperature of PTFE is 260°C. However, this difference in structure makes FEP resin have a fairly definite melting point and can be molded and processed by general thermoplastic processing methods, greatly simplifying the processing technology. This is not available in PTFE. This is the main purpose of modifying polytetrafluoroethylene with hexafluoropropylene.